In the world of logistics, having the ability to accurately track and manage inventory is crucial to success. Fortunately, Radio Frequency Identification (RFID) technology has emerged as a revolutionary tool for streamlining supply chain operations. RFID label tracking has become increasingly popular because of the efficiency and convenience it offers.

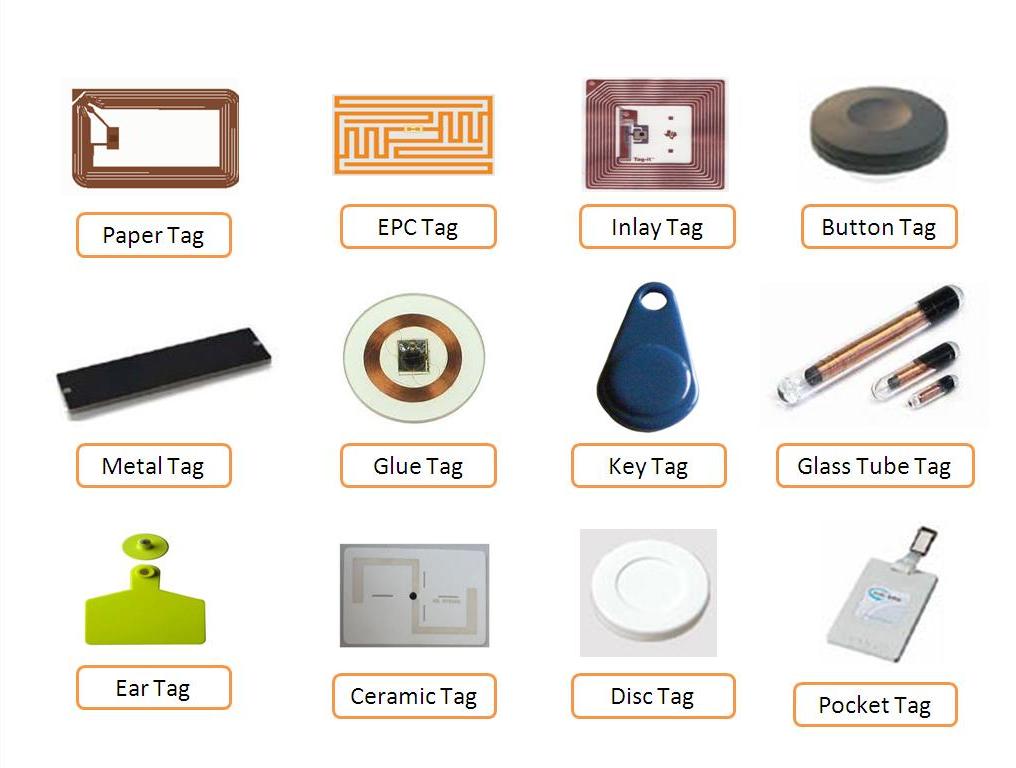

RFID tags are small devices that use radio waves to communicate with readers. They consist of a microchip and an antenna that can be attached to products or assets to enable tracking. Unlike barcodes, which require line-of-sight scanning, RFID tags can be read without physically seeing the item. This makes them ideal for tracking a wide range of products and assets, improving the efficiency and accuracy of the supply chain.

There are two types of RFID tags: Passive and Active. Passive RFID tags rely on the energy of the reader to transmit data, so they have a shorter range than active RFID tags, which have their own power source. Passive RFID tags are often used for tracking inventory in a warehouse setting, while active RFID tags are used for tracking assets that need to be monitored in real-time, such as vehicles or high-value equipment.

One of the key benefits of RFID label tracking is the ability to track large quantities of inventory quickly and accurately. This allows companies to move products through the supply chain more efficiently, reducing cycle times and increasing productivity. RFID technology also enables companies to track products in real-time, giving them better visibility into inventory levels and location, which leads to better decision-making and increased profitability.

Laundry management is another industry that benefits from RFID label tracking. Hospitals and hotels can use RFID tags to track and manage laundry items, allowing them to reduce loss and improve efficiency. The RFID tags can be easily attached to linens, towels, and other items, enabling staff to easily track and monitor inventory.

RFID label tracking is increasingly being adopted in the automotive industry, where it is used to track parts and components as they move through the supply chain. By implementing RFID technology, automotive companies are able to gain better visibility over their inventory, preventing delays and improving delivery times.

RFID technology is also being used by retailers to reduce theft and improve inventory accuracy. RFID tags can be placed on items in a store, allowing retailers to monitor inventory levels and identify when items go missing. This reduces shrinkage and improves the accuracy of inventory data.

In conclusion, RFID label tracking is a powerful tool for improving supply chain efficiency and accuracy. With the ability to track inventory in real-time, companies can make better decisions and reduce operational costs. As RFID technology continues to evolve, we can expect to see it being adopted in a wider range of industries, making supply chain management more efficient and effective than ever before.